Description

Robotic 7th Axis Slide

Overview

A 7th axis slide is a linear motion rail system that enables industrial robots to travel along a straight path beyond their fixed base. This additional axis expands the robot’s operational range, allowing it to serve multiple workstations, manage large parts, or perform tasks along extended production lines.

Key Features

-

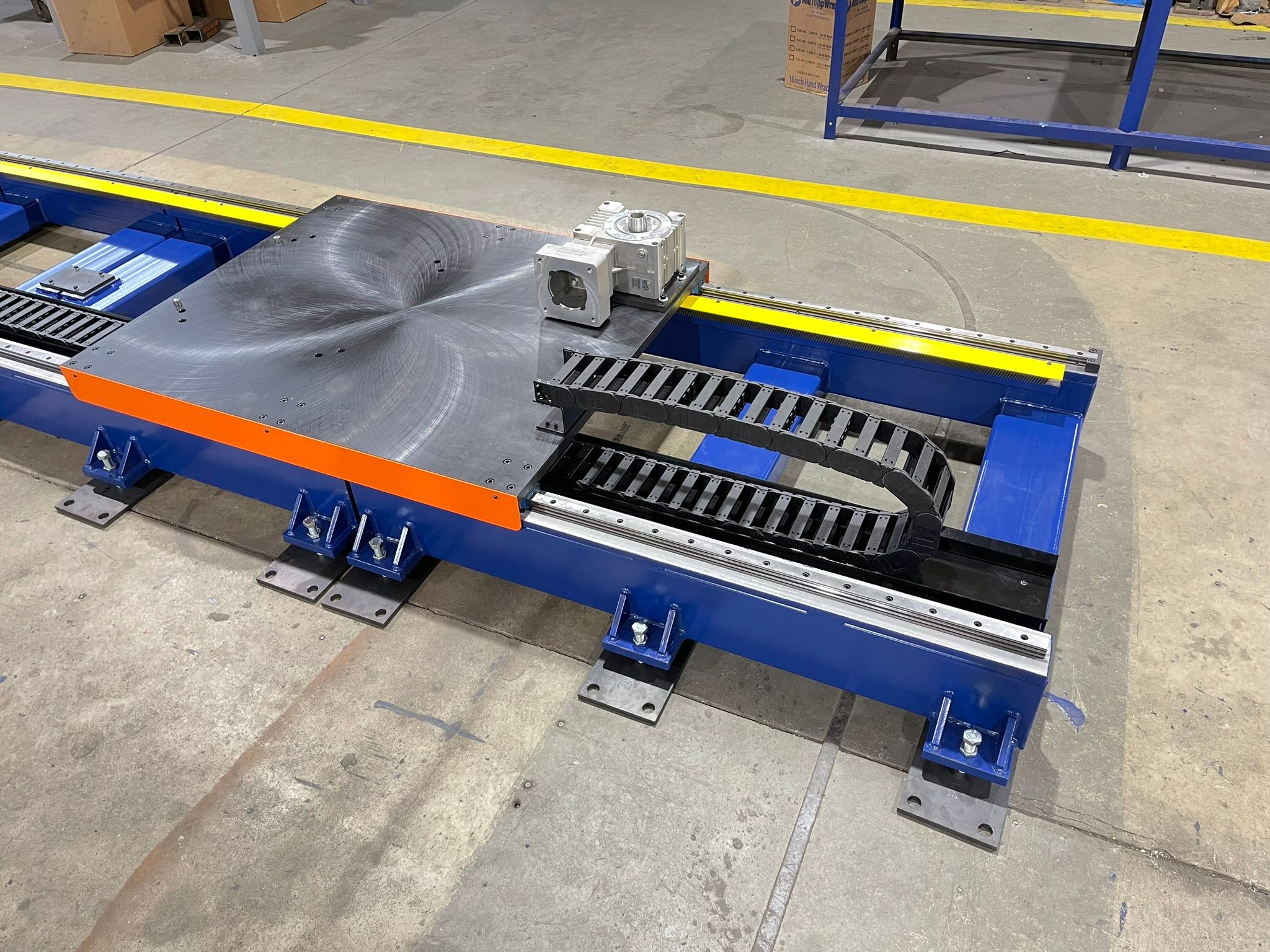

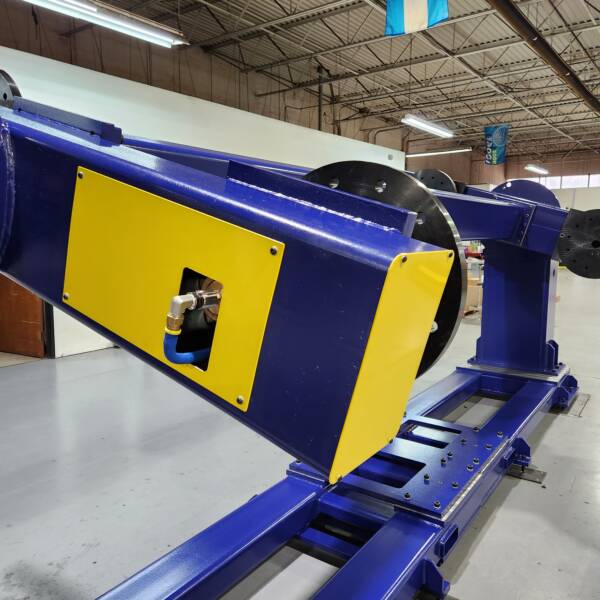

Linear Rail System

Heavy-duty steel or aluminum track engineered to support the full weight of the robot while maintaining high precision. -

Servo-Driven Carriage

The robot is mounted on a motorized carriage driven by a servo motor, fully synchronized with the robot’s control system for seamless motion. -

Extended Work Envelope

Significantly increases the robot’s working range, ideal for applications requiring mobility across multiple positions or long components. -

High Payload Capacity

Designed to handle the combined load of the robot and its payload, maintaining structural integrity and performance. -

Precision & Repeatability

Delivers high-accuracy positioning to ensure consistent and reliable operations. -

Integration Ready

Compatible with leading robot brands including ABB, FANUC, KUKA, Yaskawa, and Universal Robots.

Applications

-

Palletizing and de-palletizing at multiple stations

-

Welding of long seams or large structures

-

CNC machine tending across multiple machines

-

Automotive assembly, painting, and finishing

-

Material handling in warehouses or production lines

Optional Add-Ons

-

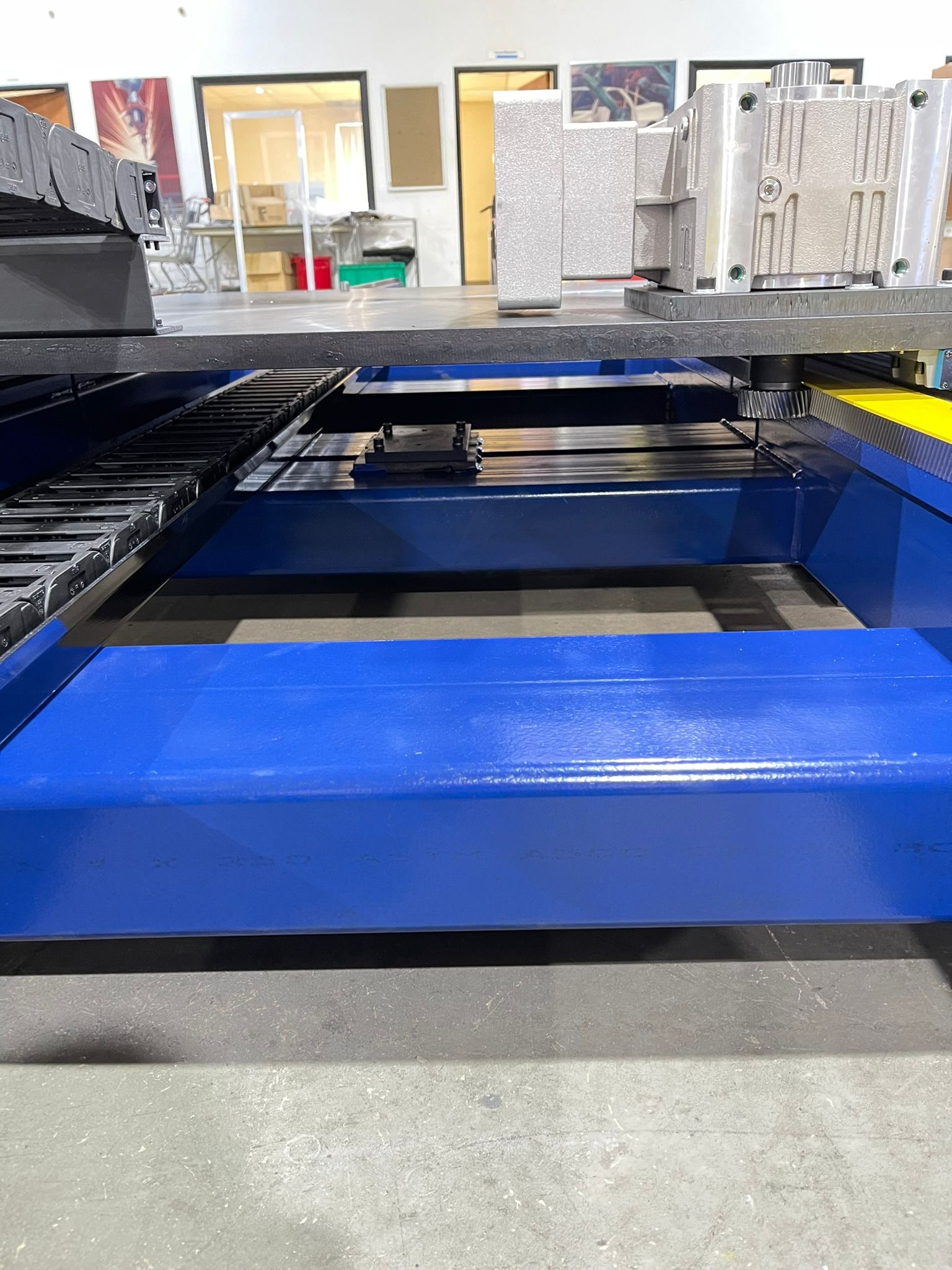

Protective bellows or enclosures

-

Cable management systems (drag chains)

-

Integrated safety sensors and limit switches

-

Custom robot mounting platforms

| Description

A3

|

Inch | Feet | Meter | Actual Adjusted | Margin | Total Price | G&R Percentage | Sales |

| 7th Axis Slide | 198 | 16.5 | 5.029 |

Reviews

There are no reviews yet.